Pricing Strategies for Custom Workholding Fixtures in Competitive Markets

Understanding Custom Workholding Fixtures

Importance of Customization in Manufacturing

Manufacturers rely on custom workholding fixtures to secure workpieces precisely during operations like machining, welding, and assembly. These fixtures ensure repeatability and accuracy, which directly impact product quality and production speed. In competitive markets, customization stands out as a key differentiator. Standard off-the-shelf solutions often fall short for complex parts, leading companies to seek tailored designs that fit specific geometries and tolerances. Custom workholding fixtures for machining, for instance, integrate seamlessly into CNC machining setups, reducing setup times and minimizing errors. Engineers design these fixtures to handle unique challenges, such as irregular shapes or high-torque applications, boosting overall efficiency in the factory. Without customization, manufacturers face increased scrap rates and downtime, eroding profits. By investing in custom workholding designs, businesses achieve higher throughput and adapt quickly to varying production demands. This approach not only enhances precision workholding but also supports scalable operations in industries like automotive and aerospace. Forward-thinking companies prioritize custom fixture manufacturing to stay ahead, turning potential bottlenecks into streamlined processes that drive innovation and reliability.

Types of Workholding Fixtures

Custom workholding fixtures come in diverse types to suit different manufacturing needs, from simple jigs to sophisticated systems. Modular workholding fixtures offer flexibility, allowing quick reconfiguration for multiple parts on the same production line. Precision workholding fixtures excel in high-accuracy environments, using materials like steel or aluminum to maintain stability under heavy loads. Industrial workholding fixtures often incorporate chucks and vises for rotational or linear holding, ideal for lathes and mills. Flexible workholding fixtures adapt to batch variations, incorporating toggle clamps or strap clamps for secure gripping without damaging surfaces. Workholding devices like grippers and locks provide quick-release mechanisms, speeding up cycle times in automated setups. Customized workholding fixtures might blend these elements, such as cam-actuated systems for multi-axis operations. Machinist workholding fixtures focus on tool accessibility, ensuring operators can reach all sides of the workpiece efficiently. In custom workholding systems, engineers select types based on the process—whether it's workholding setups for injection molding or welding. These varied options enable tailored solutions that optimize space, reduce material waste, and enhance safety in demanding factory environments.

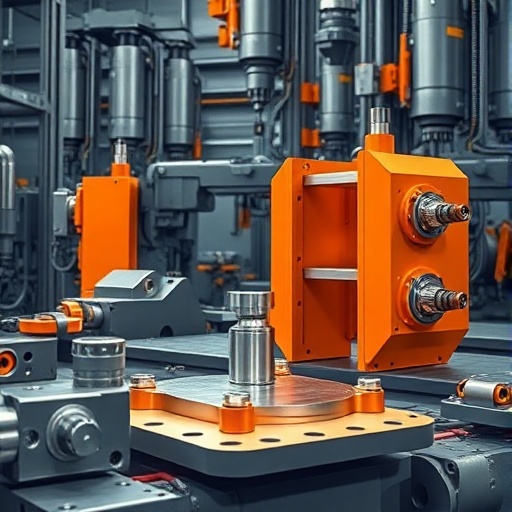

Key Components: Vises, Clamps, and Fasteners

Vises form the backbone of many custom workholding fixtures, gripping workpieces with adjustable jaws made from hardened steel for durability. Engineers often customize vise designs with extended bases or quick-change mechanisms to fit specific machining tolerances. Clamps, including toggle clamps and pneumatic variants, apply consistent pressure to hold irregular parts securely during operations like milling or welding. Toggle clamps provide rapid actuation, while strap clamps distribute force evenly across larger surfaces, preventing slippage under torque. Fasteners such as bolts, latches, and hinges integrate into fixture assemblies, allowing modular adjustments and easy maintenance. In custom workholding fixtures, these components ensure precise alignment, often incorporating bearings for smooth movement in multi-axis setups. Aluminum vises offer lightweight alternatives for high-speed applications, reducing inertia in CNC machining. Lock mechanisms and hinges enable repeatable positioning, crucial for workholding fixture design in automated lines. Tooling experts select these elements based on factors like load capacity and cycle frequency, ensuring the fixture withstands repeated use without deformation. By combining vises, clamps, and fasteners thoughtfully, manufacturers create robust workholding solutions that elevate precision and longevity in production workflows.

Pricing Strategies in a Competitive Market

Factors Influencing Pricing of Custom Fixtures

Pricing custom workholding fixtures demands careful consideration of material costs, starting with premium options like steel for heavy-duty applications or aluminum for lighter, corrosion-resistant needs. Labor-intensive design phases, involving skilled engineers and machinists, drive up expenses, especially for intricate custom machining fixtures. Complexity plays a major role—fixtures with hydraulic or pneumatic integration command higher prices due to specialized components like seals and actuators. Production volume affects economies of scale; low-volume custom work fixtures incur higher per-unit costs compared to standardized runs. Market demand for precision workholding fixtures in sectors like aerospace pushes premiums for tolerances under microns. Overhead factors, including quality control testing and certification, add layers to the final figure. Supply chain disruptions for entities like bearings or fasteners can inflate prices unexpectedly. In competitive landscapes, manufacturers balance these elements to offer value, often bundling custom workholding systems with installation support. Environmental compliance, such as eco-friendly coatings, also influences pricing. Ultimately, transparent factoring of these influences helps clients see the worth in investing in durable, efficient custom fixtures that outperform generics.

Value-Based Pricing vs. Cost-Plus Pricing

Value-based pricing for custom workholding fixtures focuses on the benefits delivered to the client, such as reduced downtime or increased output in CNC machining. Engineers calculate worth by quantifying productivity gains—like faster cycle times from optimized grippers—rather than just production costs. This strategy shines in niche markets where custom workholding designs solve unique pain points, justifying premiums for innovations that boost ROI. Clients in high-stakes industries pay more for fixtures that enhance safety or precision, viewing them as investments. In contrast, cost-plus pricing adds a fixed margin to direct expenses, including materials like vises and clamps, plus labor for fabrication. This method ensures profitability but risks undercutting perceived value in competitive bids, especially for modular workholding fixtures where flexibility adds intangible benefits. Hybrid approaches blend both, starting with costs and adjusting for value in custom fixture manufacturing. Companies using value-based tactics often conduct ROI analyses during sales, demonstrating how custom workholding fixtures cut waste and labor. Cost-plus suits straightforward projects, but value-based fosters long-term partnerships by aligning prices with client outcomes like efficiency in factory automation.

Competitive Analysis and Market Positioning

Competitive analysis reveals how rivals price custom workholding fixtures, benchmarking against leaders in custom tool fixtures and workholding equipment. Manufacturers scan market reports and trade shows to gauge trends, such as rising demand for pneumatic systems in welding applications. Positioning involves highlighting unique strengths, like rapid prototyping for custom workholding setups, to differentiate from mass-produced alternatives. In saturated markets, undercutting on price alone erodes margins, so firms emphasize quality and customization to justify higher tiers. Analyzing competitor portfolios—such as their use of automation or modular designs—guides strategic adjustments, like offering turnkey workholding solutions. Market positioning also targets segments; precision-oriented buyers value engineering expertise over cost savings. SEO-optimized outreach addresses related searches like workholding strategies and fixture design, drawing inquiries from machinists seeking tailored options. Regular audits of pricing elasticity help adapt to fluctuations in raw material costs for steel or aluminum. Successful players build brand loyalty through case studies showcasing superior performance, positioning their custom workholding fixtures as premium yet accessible in competitive arenas.

Innovations in Workholding Technology

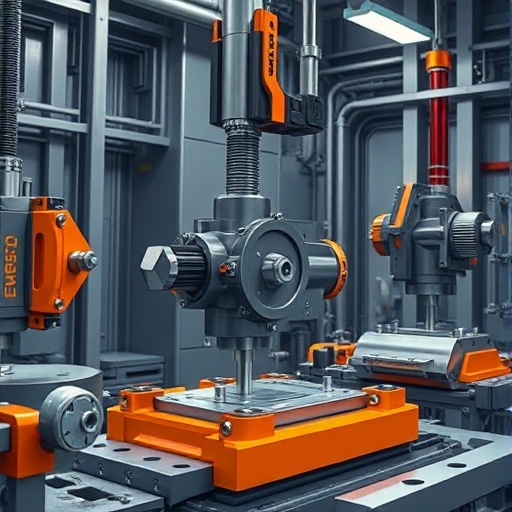

Hydraulic and Pneumatic Systems

Hydraulic systems revolutionize custom workholding fixtures by delivering powerful, consistent clamping forces for heavy-duty tasks like milling large steel components. Engineers integrate hydraulic cylinders with sensors for real-time pressure monitoring, ensuring safe operation in high-torque environments. These systems excel in applications requiring rapid actuation, reducing setup times in CNC machining by up to 50 percent. Pneumatic alternatives offer lighter, faster responses ideal for high-volume production, using air pressure to drive clamps and grippers without hydraulic fluid leaks. In custom workholding systems, pneumatic toggle clamps provide versatile holding for aluminum parts in injection molding setups. Innovations include energy-efficient valves that minimize factory air consumption, aligning with sustainability goals. Combining both—hybrid hydraulic-pneumatic fixtures—allows precise control in multi-axis machining, where hydraulic power handles coarse adjustments and pneumatics fine-tune positions. Maintenance simplifies with modular components like quick-connect hoses, extending fixture lifespan. These advancements in workholding devices enhance reliability, making them staples in modern manufacturing for seamless integration into automated lines.

Automation and Robotics in Workholding

Automation transforms custom workholding fixtures into smart systems, incorporating robots for dynamic gripping in factory automation. Robotic grippers with adaptive end-effectors replace static vises, handling varied part sizes without manual reconfiguration. Engineers program these for seamless transitions in welding or assembly lines, boosting efficiency through 24/7 operation. Custom workholding fixtures now feature embedded sensors that communicate with robotic arms, optimizing clamp force via torque feedback to prevent damage. In CNC machining, automated chucks and locks enable zero-point positioning, slashing changeover times. Innovations like collaborative robots (cobots) pair with flexible workholding fixtures, allowing machinists to oversee while bots manage repetitive tasks. This synergy cuts labor costs and errors, particularly in high-precision environments. Workholding tools with IoT connectivity predict maintenance needs, minimizing downtime. As factory automation advances, these robotic integrations position custom workholding as pivotal for scalable, intelligent manufacturing ecosystems.

Design for Manufacturing Innovations

Design for manufacturing innovations streamline custom workholding fixture creation, emphasizing simplicity and cost-effectiveness from the outset. Engineers apply principles like minimizing part count in fixture designs, using standard components such as hinges and latches to accelerate prototyping. Advanced CAD software simulates stress on vises and clamps under real machining loads, refining designs before fabrication. Innovations include topology optimization, lightening aluminum structures without sacrificing strength for pneumatic systems. In custom machining fixtures, self-aligning features reduce setup errors, enhancing workholding fixture systems' usability. Sustainable practices, like recyclable steel tooling, integrate into designs to meet regulatory demands. Collaborative platforms allow machinists and engineers to iterate quickly, incorporating feedback for optimal efficiency. These methods cut lead times by 30 percent, making custom workholding designs more agile in competitive markets. Forward-looking innovations focus on scalability, ensuring fixtures adapt to evolving production needs like multi-axis milling.

Quality Control and Efficiency in Fixture Design

Engineering Standards for Custom Fixtures

Engineering standards guide the creation of custom workholding fixtures, ensuring compliance with ISO and ASME guidelines for precision and safety. Engineers specify tolerances for components like bearings and fasteners, verifying they withstand operational stresses in machining environments. Material selection adheres to standards, favoring hardened steel for vises in high-torque applications or aluminum for lightweight pneumatic setups. Finite element analysis (FEA) tests fixture integrity, simulating weld and clamp forces to prevent failures. Custom workholding systems must meet industry benchmarks for repeatability, often certified through third-party audits. Standards also cover ergonomics, designing locks and hinges for easy machinist access to reduce injury risks. In fixture design, adherence to these protocols builds trust, enabling seamless integration into CNC machining workflows. Ongoing updates to standards incorporate innovations like automation compatibility, keeping custom fixtures relevant and reliable in dynamic manufacturing landscapes.

Role of Quality Control in Manufacturing

Quality control anchors the reliability of custom workholding fixtures, involving rigorous inspections at every stage from design to deployment. Machinists perform dimensional checks on vises and clamps using CMMs, ensuring micron-level accuracy for precision workholding. Non-destructive testing detects flaws in steel welds or aluminum castings, preventing catastrophic failures during operation. In custom fixture manufacturing, statistical process control (SPC) monitors variables like torque in pneumatic systems, maintaining consistency across batches. Traceability systems log component sourcing for fasteners and bearings, facilitating quick recalls if issues arise. Quality control extends to field performance, with feedback loops refining future workholding designs. This proactive role minimizes defects, safeguards equipment, and upholds efficiency in welding and milling applications. By embedding quality control, manufacturers deliver fixtures that exceed expectations, fostering client loyalty and reducing long-term costs.

Maximizing Efficiency with Modular and Flexible Designs

Modular designs in custom workholding fixtures allow interchangeable components like grippers and chucks, enabling rapid reconfiguration for diverse parts. Engineers build flexibility into systems with standardized interfaces, such as quick-release latches, streamlining changes in CNC machining setups. These approaches cut downtime by 40 percent, as machinists swap modules without full disassembly. Flexible workholding fixtures incorporate adjustable straps and toggles for varying workpiece sizes, ideal for batch production in injection molding. Efficiency surges through reduced inventory needs, as one modular base supports multiple tools. Innovations like parametric modeling speed custom iterations, optimizing for factory automation. In welding, modular clamps ensure consistent positioning, enhancing weld quality. By prioritizing modularity, manufacturers achieve versatile workholding solutions that adapt to market shifts, maximizing ROI through sustained productivity gains.

Case Studies: Successful Custom Workholding Implementations

Turnkey Solutions in CNC Machining

A mid-sized automotive supplier implemented turnkey custom workholding fixtures for CNC machining, integrating hydraulic vises and robotic grippers into a single system. Engineers designed the setup to handle multi-axis operations on aluminum engine blocks, achieving sub-10-micron tolerances. The turnkey approach included on-site installation and training for machinists, reducing initial setup from weeks to days. Post-implementation, cycle times dropped 35 percent, with zero defects in the first quarter. Custom workholding systems featured modular chucks for quick part changes, boosting throughput in high-volume runs. Quality control verified torque specifications, ensuring reliable clamping. This solution not only streamlined factory automation but also lowered tooling costs by 20 percent through durable steel components. The supplier's success highlights how turnkey custom machining fixtures deliver immediate value, transforming complex workflows into efficient, predictable processes.

Applications of Custom Fixtures in Welding and Milling

In a heavy equipment manufacturer, custom workholding fixtures enhanced welding and milling operations for steel frames. Pneumatic clamps and strap mechanisms secured components during robotic welding, maintaining alignment for precise seams. For milling, vise-mounted fixtures with cam locks handled high-torque cuts on large plates, minimizing vibrations. Engineers incorporated hinges for multi-angle access, allowing welders to reach tight spots efficiently. Custom fixtures reduced fixturing time by 25 percent, with modular designs adapting to varying frame sizes. In milling applications, integrated bearings ensured smooth axis movement, improving surface finishes. Quality checks confirmed fastener integrity under heat cycles. These implementations showcased custom workholding's versatility, elevating productivity in demanding environments like construction equipment production and proving essential for scalable manufacturing.

Impact of Custom Workholding on Productivity and ROI

Custom workholding fixtures profoundly boost productivity and ROI across industries, as seen in an aerospace firm's adoption of precision systems for titanium parts. Tailored grippers and locks in CNC setups cut scrap rates by 15 percent, directly increasing yield. Efficiency gains from automated pneumatic actuation shortened production cycles, enabling 20 percent more output per shift. ROI materialized within six months, with initial fixture costs recouped through labor savings and reduced rework. Case studies reveal modular designs yield compounding benefits, as flexible workholding adapts to new contracts without major reinvestments. In welding lines, custom clamps ensured consistent quality, slashing inspection times. Overall, these fixtures enhance machinist workflows, optimize tool life, and support factory automation, delivering measurable returns that justify premiums in competitive markets. Long-term, they foster innovation, positioning companies for sustained growth.