Unlocking the Secrets of Efficient Medical Gas Manifold Design

Understanding Medical Gas Manifolds

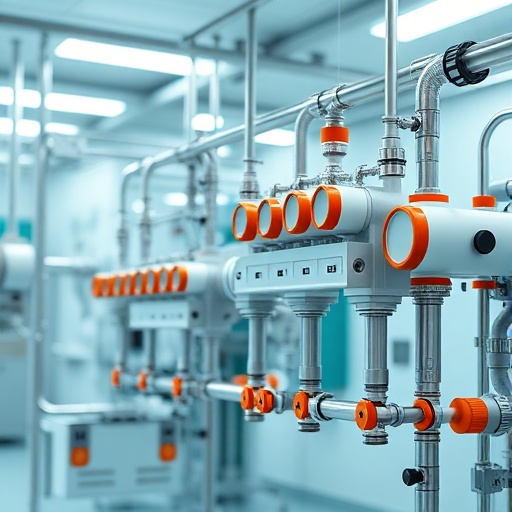

Components of a Medical Gas Manifold

Medical gas manifolds form the backbone of any reliable medical gas delivery system, coordinating the supply from multiple sources into a unified output for hospitals and clinics. Engineers design these manifolds to handle high-pressure gas cylinders or liquid sources, ensuring seamless integration into broader medical gas distribution networks. Core components include the header bars, which connect to gas cylinders via pigtails—flexible hoses that link individual cylinders to the manifold body. Switchover valves automatically detect when one bank of cylinders depletes and shift to a reserve bank, preventing interruptions in supply. Pressure regulators maintain consistent output, while check valves prevent backflow that could contaminate lines. In a complex manifold setup, collectors and manifolds gather gases like oxygen and nitrous oxide, routing them through piping systems to outlets across the facility. Safety features such as relief valves and alarms integrate directly, alerting staff to anomalies in pressure or flow. Manufacturers in the USA prioritize durable construction, often using corrosion-resistant materials to withstand the rigors of constant use in healthcare environments. These elements combine to create a manifold system that supports uninterrupted medical gas supply, critical for patient care in operating rooms and ICUs. Without robust components, efficiency drops, risking delays in procedures that demand precise gas delivery.

Types of Medical Gases Supplied

Hospitals rely on medical gas manifolds to distribute essential medical gases supplied, including oxygen, the lifeblood for respiratory support in countless treatments. Nitrous oxide, or N2O, flows through dedicated lines for anesthesia, blending with oxygen to provide safe sedation during surgeries. Medical air, compressed and filtered to pharmaceutical standards, powers pneumatic equipment and ventilators. Carbon dioxide aids in minimally invasive procedures like laparoscopy, while vacuum systems pull fluids during suction tasks. Some manifolds handle specialized gases like helium-oxygen mixtures for patients with severe asthma. Liquid oxygen storage integrates into larger systems, vaporizing the cryogen into usable gas via dedicated evaporators connected to the manifold. In the USA, facilities stock gas cylinders for these medical gases, with manifolds designed to switch between high-pressure cylinders and bulk liquid tanks for efficiency. Nitrous oxide cylinders, marked distinctly, prevent mix-ups in manifold supply lines. Engineers configure gas manifolds to segregate these types, avoiding cross-contamination that could endanger patients. Vacuum manifolds, often separate, ensure negative pressure without interfering with positive gas flows. This variety underscores the manifold's role in tailoring medical gas solutions to specific healthcare needs, from emergency rooms to dental offices.

Importance of Medical Gas Distribution in Healthcare

Effective medical gas distribution anchors healthcare operations, delivering oxygen and other gases precisely where needed to sustain life. In hospitals, manifolds ensure that operating theaters receive uninterrupted nitrous oxide and oxygen blends, enabling surgeons to focus on precision rather than supply worries. Emergency departments depend on rapid manifold systems to provide medical air for nebulizers, speeding recovery for respiratory distress patients. Without reliable distribution, delays cascade into critical risks, amplifying the stakes in high-pressure environments. Manifolds streamline this process, centralizing control to minimize waste and optimize flow, which cuts costs while boosting efficiency. In the USA, regulatory bodies like NFPA emphasize standardized medical gas systems to safeguard patient safety across facilities. Piping networks fed by manifolds reach every corner, from ICUs to recovery wards, supporting ventilators that keep vulnerable patients breathing. Medical gas equipment, including these manifolds, integrates with alarms and monitors to flag issues instantly, preventing hypoxia or over-pressurization. Healthcare providers credit well-designed distribution for reducing downtime, allowing staff to deliver care without logistical hurdles. As facilities expand, scalable manifold systems adapt, ensuring growing demands for medical gases supplied don't overwhelm infrastructure. This backbone of distribution not only saves lives but elevates overall operational resilience in modern medicine.

Design Principles for Efficient Manifolds

Key Design Considerations for Manifolds

Engineers craft medical gas manifold designs with modularity in mind, allowing easy expansion as hospital needs evolve. Capacity planning drives the layout, balancing cylinder counts against peak demand to avoid shortages during surges. Flow dynamics shape the internal pathways, minimizing turbulence that could erode efficiency in gas manifolds. Redundancy builds in duplicate lines for oxygen and N2O, ensuring failover without halting medical gas supply. Space constraints in tight hospital closets demand compact footprints, yet designs incorporate accessible panels for quick servicing. Pressure drop calculations guide pipe sizing, preventing losses that starve downstream outlets. In complex manifold setups, zoning separates medical gases supplied like vacuum from positives, reducing interference. USA-based engineering firms simulate loads to test designs, refining for real-world stresses like temperature swings. Ergonomics factor in, with color-coded pigtails and clear labeling to speed technician interactions. Sustainability enters the equation, favoring low-leakage seals that conserve gases. These considerations transform a basic manifold system into a powerhouse of reliability, supporting seamless medical gas delivery system operations. By prioritizing foresight, designs achieve longevity, often lasting decades with minimal upgrades.

Compliance with NFPA and ISO Standards

Medical gas manifolds must adhere to NFPA 99 standards, which dictate safe installation and operation in healthcare settings across the USA. These guidelines cover everything from manifold pressure ratings to alarm integrations, ensuring systems withstand emergencies like power failures. ISO 7396-1 complements this, setting international benchmarks for medical gas pipeline systems, including manifold components. Compliance demands rigorous testing for leak rates below 1% annually, safeguarding patient safety in oxygen and nitrous oxide delivery. Engineers incorporate NEMA-rated enclosures to protect electrical controls from hospital humidity and dust. NFPA requires automatic shutoffs on manifolds to isolate faults, while ISO emphasizes material purity to avoid contaminants in medical gases supplied. Certification processes involve third-party audits, verifying that gas manifolds meet seismic and fire resistance criteria. In manifold supply chains, manufacturers document traceability for every cylinder connection, from pigtails to headers. Non-compliance risks shutdowns and liabilities, so designs embed these standards from inception. Hospitals benefit from peace of mind, knowing their medical gas equipment aligns with global best practices. Ongoing updates to NFPA and ISO keep innovations viable, pushing manifold systems toward even higher efficiency and safety thresholds.

Material Selection: Nylon vs. Other Options

Nylon emerges as a top choice for medical gas manifold components, prized for its flexibility and chemical resistance in pigtail hoses. This polymer withstands the corrosive nature of gases like nitrous oxide without degrading, ensuring long-term efficiency in gas manifolds. Compared to brass fittings, nylon cuts weight, easing installation in crowded hospital piping systems. Stainless steel offers superior durability for high-pressure sections, resisting oxidation in oxygen-rich environments. Copper tubing, traditional in medical piping systems, provides excellent conductivity but demands careful brazing to avoid leaks. Engineers weigh nylon's cost-effectiveness against metal's robustness; nylon suits low-vibration areas, while alloys handle dynamic stresses in complex manifolds. In the USA, FDA-approved nylons meet purity standards for medical gas supply, preventing particulates from entering patient lines. Composite materials blend nylon with reinforcements for hybrid strength, ideal for vacuum manifolds under constant pull. Selection hinges on gas type—nylon excels with N2O, steel with pure oxygen. Lifecycle analysis favors nylon for recyclability, aligning with sustainable medical gas system manufacturing. Ultimately, blending these options creates manifolds that balance performance, safety, and economy in healthcare delivery.

Optimizing Performance and Safety

Pressure Management and Flowmeters

Pressure management in medical gas manifolds hinges on precise regulators that step down cylinder pressures from 2200 psi to safe 50-55 psi outlets. Flowmeters, calibrated for accuracy, meter oxygen and medical air to exact therapeutic levels, preventing over-delivery that strains patients. Digital variants integrate with manifold systems, displaying real-time data for nurses monitoring nitrous oxide in labor rooms. Engineers design these to compensate for altitude variations in USA facilities, maintaining consistent performance. Backup regulators ensure redundancy, kicking in if primaries falter during peak demands. In gas manifolds, orifice plates fine-tune flow, reducing noise and vibration in hospital corridors. Calibration schedules, per NFPA, keep flowmeters reliable, with annual checks averting drifts that compromise efficiency. Smart flowmeters log usage, aiding inventory for medical gases supplied and flagging anomalies like blockages. This optimization extends to vacuum lines, where regulators prevent implosions. Hospitals see fewer incidents and lower waste, as tuned systems deliver just enough gas. Integrating these tools elevates manifold supply from reactive to proactive, enhancing overall medical gas distribution reliability.

Role of Solenoids and Heaters

Solenoids in medical gas manifolds act as electric gatekeepers, opening or closing valves to control gas flow from cylinders to piping. These electromagnetic devices respond instantly to signals, isolating sections during maintenance without disrupting hospital operations. In nitrous oxide lines, solenoids prevent backflow, crucial for patient safety in anesthesia setups. Heaters, often wrapped around liquid oxygen vaporizers, ensure steady gas output by countering ambient cold that could slow evaporation. Electric models, NEMA-rated for damp environments, maintain temperatures above dew points to avoid condensation in manifolds. Engineers pair solenoids with fail-safe springs, defaulting to closed positions on power loss. In complex manifold designs, zoned solenoids enable selective shutoffs, minimizing downtime. Heaters integrate sensors to modulate power, optimizing energy use in medical gas equipment. USA manufacturers test these for endurance, simulating thousands of cycles to guarantee reliability. Together, they boost efficiency by stabilizing pressure and flow, reducing strain on downstream components. Facilities report smoother deliveries, with solenoids and heaters underpinning the seamless medical gas solutions that define modern healthcare.

Ensuring Patient Safety in Gas Delivery

Patient safety in gas delivery starts with manifolds engineered to eliminate contamination risks, using antimicrobial linings in piping to block bacterial growth. Alarms on manifolds blare at pressure deviations, alerting staff before oxygen shortages reach bedsides. Segregated lines for medical gases supplied like N2O and vacuum prevent crossovers that could deliver wrong mixtures. Lockout mechanisms secure cylinder changes, avoiding accidental releases in busy hospitals. NFPA-mandated zone valves allow quick isolation of faulty sections, protecting entire wings. Flowmeters with anti-tamper seals ensure dosages stay accurate, vital for neonates on precise oxygen. In the USA, training programs emphasize manifold checks, fostering a culture of vigilance. Redundant sensors monitor for leaks, integrating with building management for rapid response. Designs incorporate burst discs to vent excess pressure harmlessly. These layers create a fortress around delivery, where even minor flaws get caught early. Healthcare teams trust these systems, focusing on care rather than crises. Ultimately, robust safety in manifold systems saves lives, turning potential hazards into reliable lifelines.

Installation and Maintenance Best Practices

Piping Systems and Connection Techniques

Installing medical piping systems begins with mapping routes that minimize bends, preserving flow efficiency from manifolds to outlets. Brazed copper joints create airtight seals for oxygen lines, while compression fittings suit quick nitrous oxide connections. Pigtails attach cylinders to manifold headers with swaged ends, ensuring vibration resistance in hospital basements. Engineers route vacuum piping separately, using larger diameters to handle high volumes without collapse. In the USA, licensed technicians follow ISO protocols, pressure-testing assemblies to 1.5 times operating levels before commissioning. Color-coding—green for oxygen, blue for N2O—guides installers, reducing errors in complex setups. Support brackets secure runs against seismic activity, per NFPA. For liquid oxygen feeds, insulated lines prevent frosting, integrating seamlessly with manifold vaporizers. Connection techniques like orbital welding yield flawless seams, ideal for medical gas delivery systems. Post-install, purging flushes debris, verifying purity before go-live. These practices build durable networks, supporting manifold systems that endure daily rigors. Hospitals gain scalable infrastructure, ready for expansions without full overhauls.

Routine Maintenance for Enhanced Efficiency

Routine maintenance keeps medical gas manifolds running at peak efficiency, with quarterly visual inspections spotting worn pigtails or loose fittings. Technicians calibrate flowmeters and regulators annually, adjusting for drifts that sap performance in gas cylinders feeds. Cleaning headers removes residue from nitrous oxide, preventing clogs in manifold supply paths. NFPA schedules mandate leak tests using soap solutions or ultrasonic detectors, sealing vulnerabilities before they worsen. Lubricating solenoids extends their life, ensuring swift responses in emergencies. For heaters, thermal imaging checks even distribution, averting cold spots in oxygen vaporization. USA facilities log all activities in digital systems, tracking trends for predictive upkeep. Cylinder inspections verify valve integrity, swapping out dated ones to maintain pressure stability. Vacuum pumps get oil changes, sustaining pull without energy spikes. These steps cut downtime by 30%, per industry reports, while extending manifold lifespan. Staff training reinforces protocols, embedding efficiency into daily operations. Proactive care transforms manifolds from liabilities to assets, fueling reliable medical gas distribution.

Troubleshooting Common Issues in Manifold Systems

Troubleshooting manifold systems starts with diagnosing low pressure, often tracing to depleted cylinders or faulty switchovers in gas manifolds. Technicians swap banks manually if automatics stick, restoring oxygen flow swiftly. Leaks manifest as hisses; pinpoint them with electronic sniffers, tightening pigtail connections or replacing diaphragms. Flowmeter inaccuracies signal calibration needs, resolved by bench-testing against standards. Solenoid failures, humming without action, require coil checks or power supply verifications. In nitrous oxide lines, oxide buildup clogs regulators—disassemble and flush with approved solvents. Vacuum drops point to pump wear; monitor gauges and service accordingly. NFPA guides isolate issues via zone valves, minimizing disruption in hospitals. For complex manifolds, software diagnostics scan sensors, flagging electrical glitches. USA experts document fixes, building a knowledge base for faster resolutions. Heater malfunctions, like uneven warming, stem from thermostat faults—replace and retest. These systematic approaches resolve 90% of problems on-site, upholding patient safety and efficiency. Early intervention prevents escalations, keeping medical gas supply uninterrupted.

Future Trends in Medical Gas Manifold Systems

Innovations in Medical Gas Equipment

Innovations in medical gas equipment redefine manifold capabilities, with modular designs allowing plug-and-play upgrades for evolving hospital needs. Advanced composites replace traditional metals in pigtails, slashing weight while boosting corrosion resistance for oxygen and N2O handling. Compact vaporizers integrate directly into manifolds, streamlining liquid-to-gas conversion for space-strapped facilities. In the USA, 3D-printed components enable custom fits, accelerating medical gas system manufacturing. Sensor-embedded headers detect micro-leaks in real-time, alerting via apps before issues escalate. Hybrid manifolds blend cylinder and pipeline inputs, optimizing for variable demands in ICUs. Flowmeters evolve to wireless models, transmitting data to central dashboards for proactive tweaks. Sustainability drives biodegradable seals in vacuum lines, reducing environmental impact. These breakthroughs enhance efficiency, cutting energy use by up to 20%. Engineers collaborate with biotech firms, embedding antimicrobial tech into piping for infection control. As innovations proliferate, manifolds become smarter, more adaptive pillars of healthcare infrastructure.

Integration of Smart Technology in Medical Gas Supply

Smart technology transforms medical gas supply, embedding IoT sensors in manifolds to monitor pressure, flow, and temperature remotely. AI algorithms predict cylinder depletion, auto-ordering refills to avert shortages in nitrous oxide stocks. In hospitals, apps let staff view manifold status on mobiles, enabling instant adjustments during surges. Blockchain tracks gas provenance from cylinders to outlets, ensuring compliance in USA regulations. Wireless solenoids respond to voice commands, speeding emergency isolations. Integration with EHRs flags usage patterns, optimizing medical gases supplied for specific patients. Cloud analytics crunch data across facilities, refining designs for next-gen gas manifolds. Vacuum systems gain predictive maintenance, vibrating alerts for pump servicing. These tools slash response times, boosting efficiency in complex setups. Security protocols encrypt data, guarding against cyber threats in connected medical gas delivery systems. Forward-thinking manufacturers lead this shift, delivering manifolds that anticipate needs rather than react, revolutionizing healthcare reliability.

Sustainability in Medical Gas System Manufacturing

Sustainability shapes medical gas system manufacturing, with recyclable nylons supplanting disposables in pigtails and headers. Solar-powered heaters reduce carbon footprints in oxygen vaporizers, aligning with green hospital initiatives. In the USA, low-emission welding cuts volatile compounds during manifold assembly. Waterless testing protocols conserve resources in quality checks for gas cylinders. Biodegradable lubricants service solenoids, minimizing waste in maintenance cycles. Engineers design energy-efficient switchovers, drawing minimal power for seamless bank shifts. Recovered gases from expired cylinders feed recycling loops, extending lifecycle of medical gases supplied. ISO standards now include eco-metrics, pushing manufacturers toward net-zero goals. Modular manifolds facilitate upgrades, avoiding full replacements and e-waste. Vacuum components use recycled alloys, maintaining strength without mining impacts. These practices not only lower costs but elevate brand trust in eco-conscious healthcare. As trends accelerate, sustainable manufacturing ensures manifolds support healing without harming the planet, blending innovation with responsibility.